Mobile Manipulation Capstone

Overview

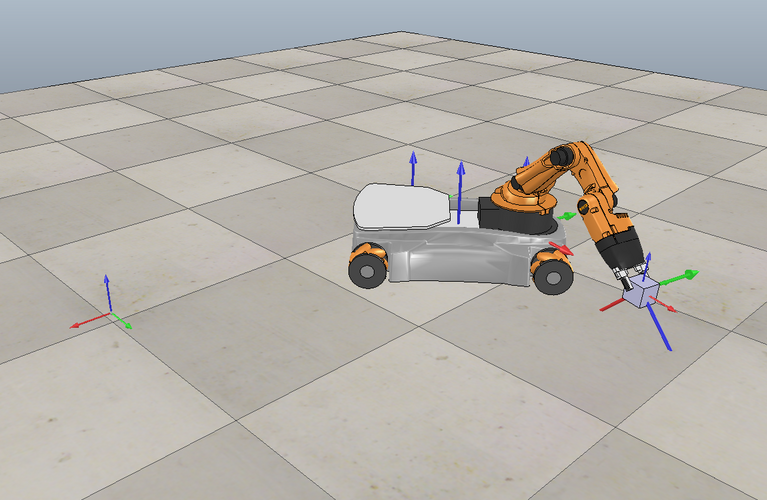

Developed a full planning and control system for a simulated youBot mobile manipulator. The robot autonomously executed a pick-and-place task by integrating kinematics, trajectory generation, and feedback control.

How It Works

Kinematics & State Propagation: Implemented odometry and joint updates with speed constraints.

Trajectory Generation: Designed smooth, time-parameterized end-effector motions for pick-and-place.

Feedback Control: Combined feedforward twists with proportional–integral pose error correction using the system Jacobian.

Simulation: Logged configurations and errors to run in CoppeliaSim, validating accurate task completion.

Impact

Demonstrated skills in robotics kinematics, control, and simulation while delivering a complete, functioning mobile manipulation system.

Mobile Manipulation Report

Program Components

Wrapper (click to expand)

%% General

clear all

clc

close all

warning('off','all')

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%This code takes the initial inputs of joint angles, joint velocities, all

%fixed configuration (T) matrices, and control variables and generates a

%controlled trajectory for a pick and place UR5 robot.

%Using the input fixed configuration matrices, the desired trajectory is generated.

%Then, using forward kinematics and other fixed configuration

%matrices, the actual current initial configuration is calculated. Both are

%fed into the loop.

% In the loop, the current desired and next desired T matrices, feed into FeedbackControl

%along with actual current Tse matrix, arm joint angles, and controllers to get current

%error twist and joint velocities. Desired values are stored for plotting.

%It then takes current joint velocities and angles and feeds them into NextState to

%get out the current state of the robot. Using the current state, the

%new Tse configuration is calculated and fed back into FeedbackControl

%to restart the loop. This carries on until all trajectories have run

%through the loop.

%Running the Final.csv file in the CoppeliaSim Scene 6 will produce the

%desired pick and place task for any given block location.

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%% Initialization - Input Values Here

% Next state Initialization

%arm joint angles

a_angles = [0 .2 -1.9 -0.5 0];

%chassis position and angle

c_angles = [0 0 0];

%wheel angles

w_angles = [0 0 0 0];

%arm joint velocities

a_velocities = [0 0 0 0 0];

%wheel velocities

w_velocities = [0 0 0 0];

%max joint speed

vmax = 4*100;

% TrajectoryGenerator Initialization

% Constant T between {b} and {0}

Tb0=[1 0 0 .1662;...

0 1 0 0;...

0 0 1 .0026;...

0 0 0 1];

% e-e zero position

M0e=[1 0 0 0.033 ;...

0 1 0 0 ;...

0 0 1 0.6546;...

0 0 0 1 ];

% Arm joint screw axes in {B} frame

Blist = [[0 0 1 0 .033 0]'...

[0 -1 0 -.5076 0 0]'...

[0 -1 0 -.3526 0 0]' ...

[0 -1 0 -.2176 0 0]' ...

[0 0 1 0 0 0]'];

% Desired e-e starting config

Tse_d= [ 0 0 1 0;...

0 1 0 0;...

-1 0 0 0.5;...

0 0 0 1];

% Initial cube config.

Tsc_i=[1 0 0 .75;...

0 1 0 .25;...

0 0 1 0.025;...

0 0 0 1];

% Final cube config.

Tsc_f=[0 1 0 0;...

-1 0 0 -2;...

0 0 1 .025;...

0 0 0 1];

% e-e Gripping config.

Tce_g = [cosd(135) 0 sind(135) 0;...

0 1 0 0;...

-sind(135) 0 cosd(135) 0;...

0 0 0 1];

% e-e Standoff Config.

Tce_sf=[cosd(135) 0 sind(135) 0;...

0 1 0 0;...

-sind(135) 0 cosd(135) .1;...

0 0 0 1];

% Number of trajectory reference configs per 0.01s

k = 10;

% FeedbackControl Initialization

% Proportional control matrix

Kp = 6*eye(6,6);

% Integral control matrix

Ki = .15*eye(6,6);

% Time step

dt = 0.01;

% Initialize integral error

Xerr_i=[0 0 0 0 0 0]';

%% Initial Calculations

% Generate entire desired trajectory

N_states = TrajectoryGenerator(Tse_d,Tsc_i,Tsc_f,Tce_g,Tce_sf,k);

%Looping though N ref configurations

N=size(N_states,1);

%Calculate Initial e-e location/orientation

% forward kinematics to find Toe

Toe = FKinBody(M0e,Blist,a_angles');

% chassis angles to fid Tsb

phi=c_angles(1);

Tsb= [cos(phi) -sin(phi) 0 c_angles(2);...

sin(phi) cos(phi) 0 c_angles(3);...

0 0 1 .0963 ;...

0 0 0 1 ];

%matrix multiplication to find Tse initial

Tse=Tsb*Tb0*Toe;

%% Start of The Loop

for i= 1:N-1

% Desired Trajectory - current

Tse_d =[N_states(i,1:3) N_states(i,10);...

N_states(i,4:6) N_states(i,11);...

N_states(i,7:9) N_states(i,12);...

zeros(1,3) 1 ];

% Desired Trajectory - next

Tse_d_n =[N_states(i+1,1:3) N_states(i+1,10);...

N_states(i+1,4:6) N_states(i+1,11);...

N_states(i+1,7:9) N_states(i+1,12);...

zeros(1,3) 1 ];

% Desired gripper state

g_state = N_states(i,13);

% Input desired state - output twist

[twist, w_velocities, a_velocities, Xerr_i,Xerr,Vd,mu_w,mu_v] = FeedbackControl(Tse,Tse_d,Tse_d_n,Kp,Ki,dt,Xerr_i,w_angles',a_angles);

% Store error for plotting

Xerr_is(:,i)=Xerr_i;

Xerr_s(:,i) = Xerr;

Vd_s(:,i) = Vd;

twist_s(:,i) = twist;

Tse_d_s(:,:,i) = Tse_d;

Tse_s(:,:,i) = Tse;

mu_w_s(i) = mu_w;

mu_v_s(i) = mu_v;

% generate new state with updated twist

state(i,:) = NextState(c_angles,a_angles,w_angles,a_velocities,w_velocities,dt,vmax,g_state);

c_angles=state(i,1:3);

a_angles=state(i,4:8);

w_angles=state(i,9:12);

% Calcualte new Tse using updated state

Toe = FKinBody(M0e,Blist,a_angles');

phi=c_angles(1);

Tsb= [cos(phi) -sin(phi) 0 c_angles(2);...

sin(phi) cos(phi) 0 c_angles(3);...

0 0 1 .0963 ;...

0 0 0 1 ];

Tse=Tsb*Tb0*Toe;

end

state;

csvwrite('Final.csv',state)

%% Plots - Error Twist vs. time, Manipulability Factors (w,v) vs. time, Desired/Actual Tse vs. time

time = linspace(0,15,length(state));

% Error Twist vs. time

figure(2)

subplot(2,2,1:2)

title('Error Twist')

hold on

grid on

plot(time,Xerr_s(1,:))

plot(time,Xerr_s(2,:))

plot(time,Xerr_s(3,:))

plot(time,Xerr_s(4,:))

plot(time,Xerr_s(5,:))

plot(time,Xerr_s(6,:))

xlabel('Time of Simulation [s]')

ylabel('Error Twist')

legend('wx','wy','wz','vx','vy','vz')

%Manipulability Factors (w,v) vs. time

hold on

subplot(2,2,3)

plot(time, mu_w_s)

grid on

title('Rotational Manipulability mu_1(A_w)')

xlabel('Time of Simulation [s]')

subplot(2,2,4)

plot(time, mu_v_s)

grid on

title('Translational Manipulability mu_1(A_v)')

xlabel('Time of Simulation [s]')

% Desired/Actual Tse vs. time

figure(4)

hold on

% Subplot 1 of 3

subplot(1,3,1)

hold on

grid on

plot(time,squeeze(Tse_d_s(1,4,:)))

title('Desired X-position of e-e')

plot(time,squeeze(Tse_s(1,4,:)))

title('Actual X-position of e-e')

legend('Desired','Actual')

hold off

% Subplot 2 of 3

subplot(1,3,2)

hold on

grid on

plot(time,squeeze(Tse_d_s(2,4,:)))

title('Desired Y-position of e-e')

plot(time,squeeze(Tse_s(2,4,:)))

title('Actual Y-position of e-e')

legend('Desired','Actual')

hold off

% Subplot 3 of 3

subplot(1,3,3)

hold on

grid on

plot(time,squeeze(Tse_d_s(3,4,:)))

title('Desired Z-position of e-e')

plot(time,squeeze(Tse_s(3,4,:)))

title('Actual Z-position of e-e')

legend('Desired','Actual')

hold off

Function 1: Next State (click to expand)

%% 1 - Kinematics Simulator

% uses the kinematics of the youBot to predict how the robot will move in a small timestep given

% its current configuration and velocity.

% Inputs:

% • The current state of the robot (12 variables: 3 for chassis, 5 for arm, 4 for wheel angles)

% • The joint and wheel velocities (9 variables: 5 for arm ˙θ, 4 for wheels u)

% • The timestep size ∆t (1 parameter)

% • The maximum joint and wheel velocity magnitude (1 parameter)

% Outputs

% • The next state (configuration) of the robot (12 variables)

function state = NextState(c_angles,a_angles,w_angles,a_velocities,w_velocities,dt,vmax,g_state)

%checking for maximum velocity

for b=1:length(a_velocities)

if a_velocities(b)>=vmax || a_velocities(b)<=-vmax

a_velocities(b) = vmax;

elseif a_velocities(b)<=-vmax

a_velocities(b) = -vmax;

end

end

for c=1:length(w_velocities)

if w_velocities(c)>=vmax

w_velocities(c) = vmax;

elseif w_velocities(c)<=-vmax

w_velocities(c)=-vmax;

end

end

%euler step for arm and wheel angles

a_angles_n = a_angles + a_velocities*dt;

w_angles_n = w_angles + w_velocities*dt;

%euler step for chassis config

%odometry

r = 0.0475; %m

l = 0.47/2; %m

w = 0.3/2; %m

F = r/4*[-1/(l+w) 1/(l+w) 1/(l+w) -1/(l+w);

1 1 1 1 ;

-1 1 -1 1 ];

d_theta = w_velocities*dt;

Vb = zeros(1,6)';

Vb_i = F*d_theta';

Vb(3) = Vb_i(1);

Vb(4) = Vb_i(2);

Vb(5) = Vb_i(3);

% conditional for wbz = 0

if abs(Vb(3)) <= 1E-3

d_qb = [ 0 ;...

Vb(4) ;...

Vb(5)];

else

d_qb = [ Vb(3) ;...

(Vb(4)*sin(Vb(3)) + Vb(5)*(cos(Vb(3) -1)))/Vb(3) ;...

(Vb(5)*sin(Vb(3)) + Vb(4)*(1 - cos(Vb(3))))/Vb(3)];

end

phi_k = c_angles(1);

dq = [1 0 0 ;

0 cos(phi_k) -sin(phi_k) ;

0 sin(phi_k) cos(phi_k) ] * d_qb;

c_angles_n = c_angles + dq';

%updated states

state = [c_angles_n a_angles_n w_angles_n g_state];

end

Function 2: Trajectory Generator (click to expand)

%% 2 -TrajectoryGenerator to create the reference (desired) trajectory for the end-effector frame {e}.

% Inputs

% • The initial configuration of the end-effector: Tse,initial

% • The initial configuration of the cube: Tsc,initial

% • The desired final configuration of the cube: Tsc,f inal

% • The configuration of the end-effector relative to the cube while grasping: Tce,grasp

% • The standoff configuration of the end-effector above the cube, before and after grasping, relative to the cube:

% Tce,standof f

% • The number of trajectory reference configurations per 0.01 seconds: k. The value k is an integer with a value

% of 1 or greater. 1

% Outputs

% • A representation of the N configurations of the end-effector along the entire concatenated eight-segment reference trajectory. Each of these N reference points represents a transformation matrix Tse of the end-effector

% frame {e} relative to {s} at an instant in time, plus the gripper state (0 for open or 1 for closed). These

% reference configurations will be used by your controller. Note: if your trajectory takes t seconds, your function

% should generate N = t · k/0.01 configurations.

% • A .csv file with the entire eight-segment reference trajectory. Each line of the .csv file corresponds to one

% configuration Tse of the end-effector, expressed as 13 variables separated by commas. The 13 variables are, in

% order:

% r11, r12, r13, r21, r22, r23, r31, r32, r33, px, py, pz, gripper state

function Configurations = TrajectoryGenerator(Tse_d,Tsc_i,Tsc_f,Tce_g,Tce_sf,k)

%Trajectory Selections

method=5;%(3 for cubic, 5 for quintic)

t_l=6;%seconds large movement takes

t_s=.75;%seconds small movement takes

N_l=t_l*k/.01;%number of large movement

N_s=t_s*k/.01;%number of small movement

% 1 - gripper initial position to standoff initial open

traj_1 = ScrewTrajectory(Tse_d,Tsc_i*Tce_sf,t_l,N_l,method);

% 2 - standoff initial open to grip open

traj_2 = ScrewTrajectory(Tsc_i*Tce_sf,Tsc_i*Tce_g,t_s,N_s,method);

% 4 - grip close to standoff initial

traj_4 = ScrewTrajectory(Tsc_i*Tce_g,Tsc_i*Tce_sf,t_s,N_s,method);

% 5 - standoff initial close to standoff close final

traj_5 = ScrewTrajectory(Tsc_i*Tce_sf,Tsc_f*Tce_sf,t_l,N_l,method);

% 6 - standoff final close to grip close

traj_6 = ScrewTrajectory(Tsc_f*Tce_sf,Tsc_f*Tce_g,t_s,N_s,method);

% 8 - grip 2 open to standoff 2 open

traj_8 = ScrewTrajectory(Tsc_f*Tce_g,Tsc_f*Tce_sf,t_s,N_s,method);

for i = 1:N_l

%1 - gripper initial position to standoff 1 open

step1 = traj_1{1,i};

traj1(i,:) = [step1(1,1:3) step1(2,1:3) step1(3,1:3) step1(1:3,4)' 0];

%5 - standoff 1 close to standoff 2 close

step5 = traj_5{1,i};

traj5(i,:) = [step5(1,1:3) step5(2,1:3) step5(3,1:3) step5(1:3,4)' 1];

end

for i = 1:N_s

%2 - standoff 1 open to grip open

step2 = traj_2{1,i};

traj2(i,:) = [step2(1,1:3) step2(2,1:3) step2(3,1:3) step2(1:3,4)' 0];

%4 - grip close to standoff 1 close

step4 = traj_4{1,i};

traj4(i,:) = [step4(1,1:3) step4(2,1:3) step4(3,1:3) step4(1:3,4)' 1];

%6 - standoff 2 close to grip 2 close

step6 = traj_6{1,i};

traj6(i,:) = [step6(1,1:3) step6(2,1:3) step6(3,1:3) step6(1:3,4)' 1];

%8 - grip 2 open to standoff 2 open

step8 = traj_8{1,i};

traj8(i,:) = [step8(1,1:3) step8(2,1:3) step8(3,1:3) step8(1:3,4)' 0];

%3 - grip open to grip close

end

traj3(1,:) = [step2(1,1:3) step2(2,1:3) step2(3,1:3) step2(1:3,4)' 1];

%7 - grip 2 close to grip 2 open

traj7(1,:) = [step6(1,1:3) step6(2,1:3) step6(3,1:3) step6(1:3,4)' 0];

Configurations = [traj1; traj2; traj3; traj4; traj5; traj6; traj7; traj8];

csvwrite('test_part_2',Configurations)

Function 3: Feedback Control (click to expand)

%% 3 - FeedbackControl calculates the task-space feedforward plus feedback control law discussed in class

% Inputs

% • The current actual end-effector configuration X (aka Tse)

% • The current reference end-effector configuration Xd (aka Tse,d)

% • The reference end-effector configuration at the next timestep, Xd,next (aka Tse,d,next)

% • The PI gain matrices Kp and Ki

% • The timestep ∆t between reference trajectory configurations

% Outputs

% • The commanded end-effector twist V expressed in the end-effector frame {e} (for plotting purposes).

% • The commanded wheel speeds, u and the commanded arm joint speeds, ˙θ

function [twist, w_velocities, a_velocities,Xerr_i,Xerr,Vd,mu_w,mu_v] = FeedbackControl(Tse,Tse_d,Tse_d_n,Kp,Ki,dt,Xerr_i,w_angles ,a_angles)

%adjoint

adj = Adjoint(TransInv(Tse)*Tse_d);

%error twist

Xerr = se3ToVec(MatrixLog6(TransInv(Tse)*Tse_d));

%integral error

Xerr_i= Xerr*dt + Xerr_i;

%desired twist

Vd = se3ToVec(1/dt*MatrixLog6(TransInv(Tse_d)*Tse_d_n));

%updated twist

V = adj*Vd + Kp*Xerr + Ki*Xerr_i;

%Jacobian

% arm Jacobian

thetalist = a_angles';

Blist = [[0 0 1 0 .033 0]' ...

[0 -1 0 -.5076 0 0]' ...

[0 -1 0 -.3526 0 0]' ...

[0 -1 0 -.2176 0 0]' ...

[0 0 1 0 0 0]'];

J_arm = JacobianBody(Blist,thetalist);

% base Jacobian

Tb0 = [1 0 0 .1662 ;...

0 1 0 0 ;...

0 0 1 0.0026;...

0 0 0 1 ];

M0e = [1 0 0 0.033 ;...

0 1 0 0 ;...

0 0 1 0.6546;...

0 0 0 1 ];

Toe_theta=FKinBody(M0e,Blist,thetalist);

adj2 = Adjoint(TransInv(Toe_theta)*TransInv(Tb0));

r = 0.0475; l = 0.47/2; w = 0.3/2; %m

F = r/4*[-1/(l+w) 1/(l+w) 1/(l+w) -1/(l+w);...

1 1 1 1 ;...

-1 1 -1 1 ];...

F6 = [zeros(1,length(F));...

zeros(1,length(F));...

F;...

zeros(1,length(F))];

J_base = adj2*F6;

J = [J_base J_arm];

%manipulability values

Jw = J(1:3,:);

Aw = Jw*Jw';

lw = eig(Aw);

lw_max = max(lw);

lw_min = min(lw);

mu_w = sqrt(lw_max)/sqrt(lw_min);

Jv = J(4:6,:);

Av = Jv*Jv';

lv = eig(Av);

lv_max = max(lv);

lv_min = min(lv);

mu_v = sqrt(lv_max)/sqrt(lv_min);

% velocities

vel = pinv(J,.0001)*V;

twist=V;

w_velocities=vel(1:4)';

a_velocities=vel(5:9)';

end