Steel Shaft Design Optimization Tool

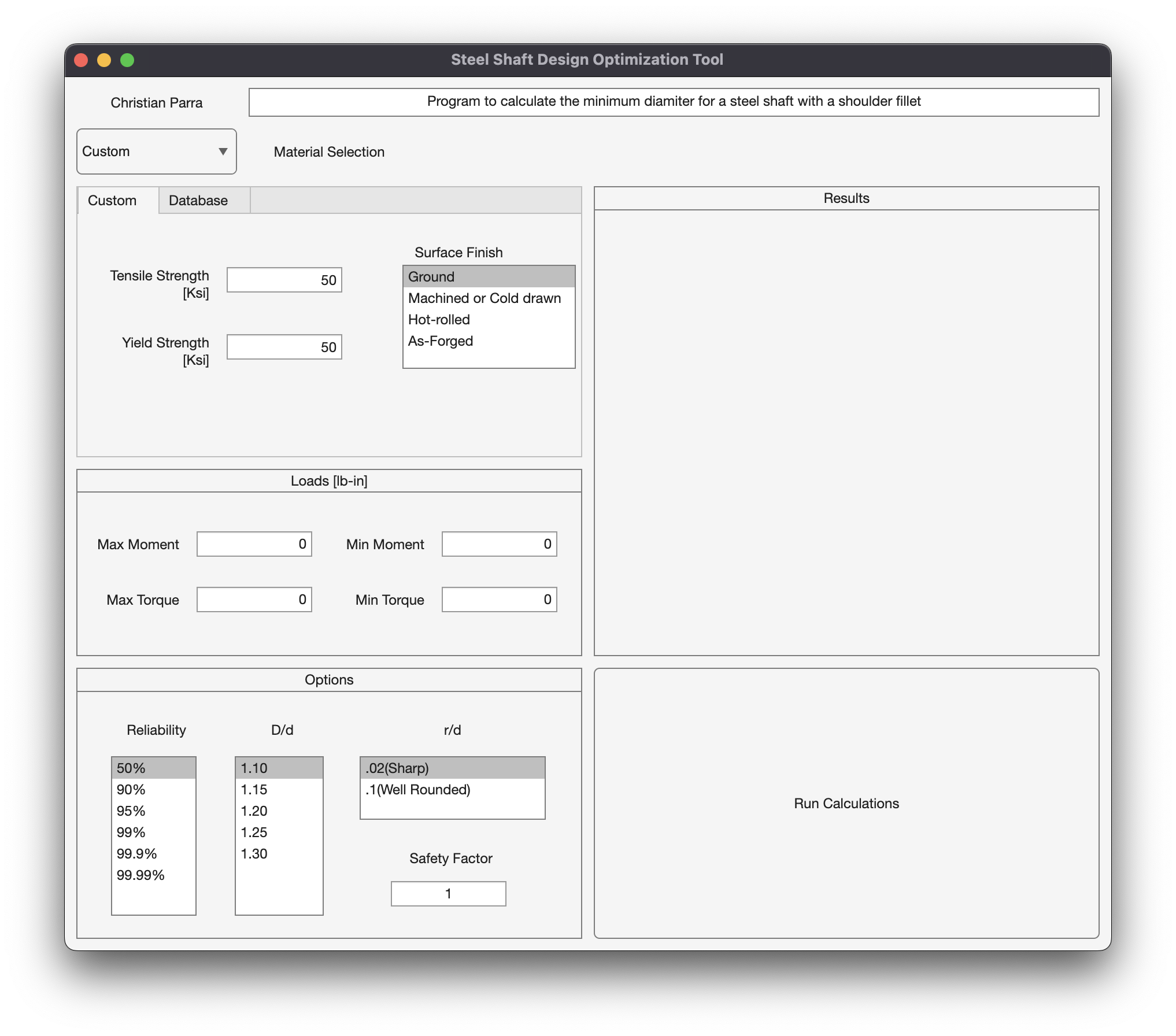

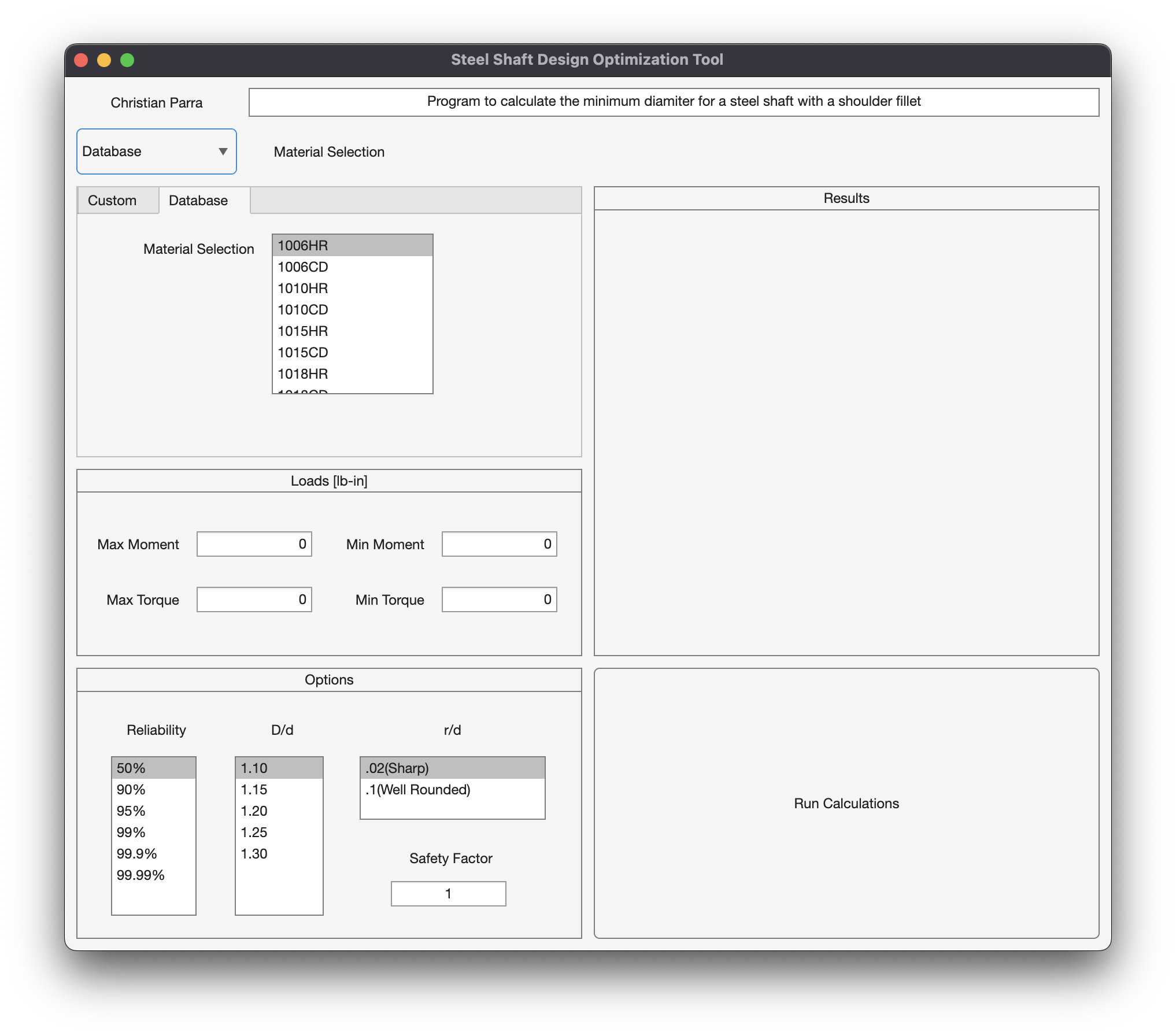

This MATLAB-based design tool optimizes shaft dimensions according to ASME fatigue criteria and user-defined safety factors, streamlining a traditionally time-consuming design process.

-

Automated Sizing: Calculates the minimum required shaft diameter from user inputs such as torque, bending moments, alternating loads, material properties, and safety factor.

-

Built-in Reliability: Incorporates automated stress concentration factor selection and ASME fatigue failure analysis, eliminating manual chart lookups while ensuring accuracy.

-

Impact: Demonstrates practical application of mechanical design principles, combining coding, fatigue analysis, and optimization to deliver efficient and reliable shaft designs.

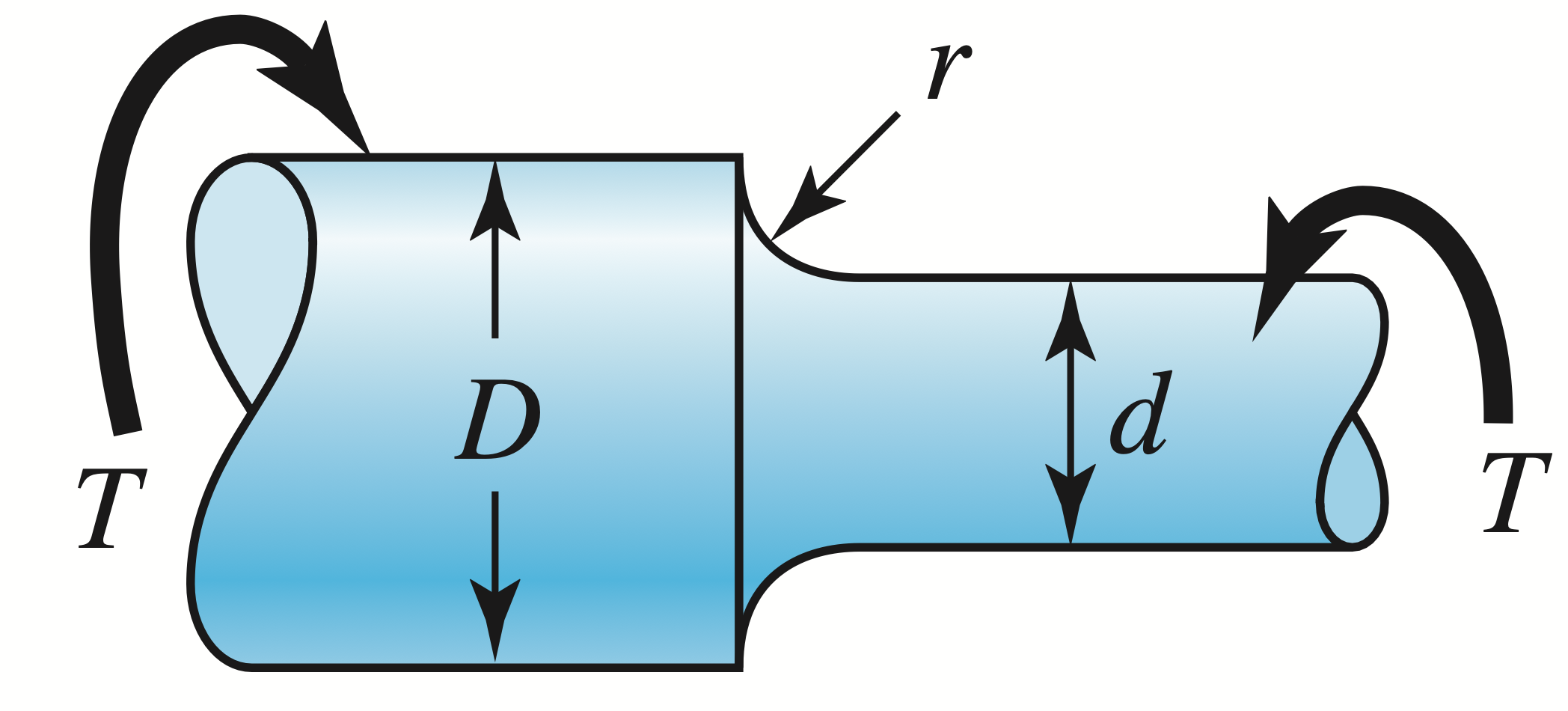

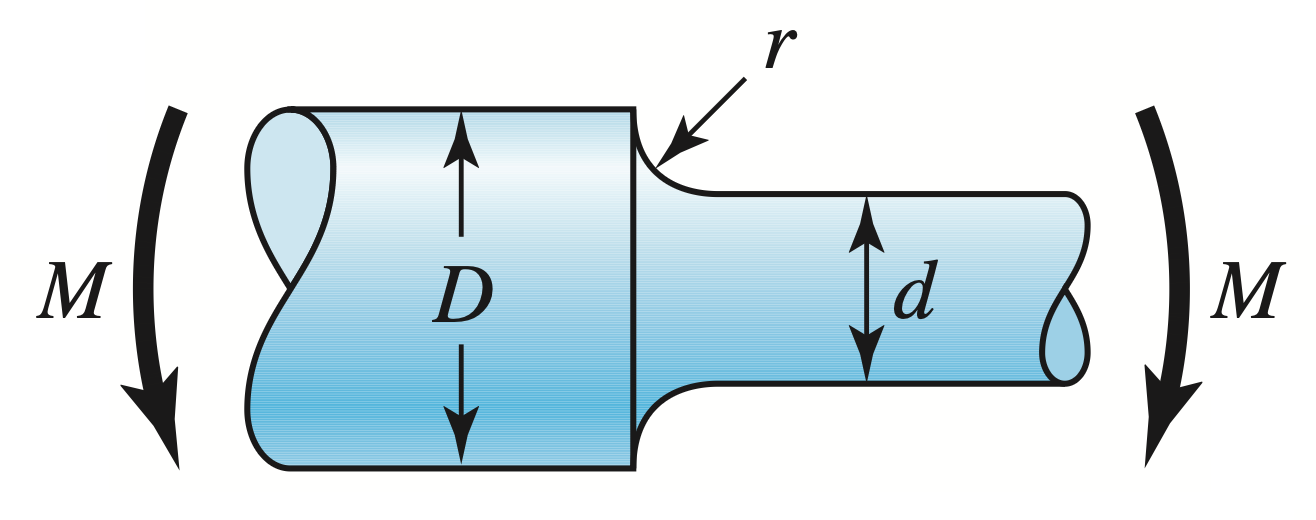

Section of Shaft with grinding-relief groove, Shigley’s Mechanical Engineering Design

Inputs

Material Properties

- Choose from a built-in list of ASME steel grades, or

- Manually input key properties: yield strength, tensile strength, and surface finish.

Loading Conditions

- Define the minimum and maximum moment and torque values the shaft will experience.

Additional Options

- Customize design parameters such as:

- Shaft reliability

- Factor of safety

- Diameter ratio (D/d)

- Shoulder fillet (r/d)

Outputs

Minimum rod diamiter required to sustain applied loads for both the small and large portion of the shaft

Default Configuration

Test Case

Project MATLAB Code (click to expand)

% MAE 190

% Steel Shaft Design Optimization Tool

% Christian Parra

% A16402854

% 3/17/2024

% all calculations are made in imperial units[lb,in,ksi/psi]

%-------------------------------------------------------------------------

% user interface for shaft criteria

function mae190test()

comp=uifigure('Name',"Steel Shaft Design Optimization Tool");

comp.Position = [1 1 905 756];

% Create GridLayout

g = uigridlayout(comp);

g.ColumnWidth = {'1x', '1x', '1x', '1x', '1x', '1x'};

g.RowHeight = {25, 40, '1x', '1x', 40, '1x', '1x', '1x'};

% Create LabeloftextareaTextAreaLabel

ga = uilabel(g);

ga.HorizontalAlignment = 'center';

ga.Layout.Row = 1;

ga.Layout.Column = 1;

ga.Text = 'Christian Parra';

% Create MAE190APPTextArea

gb = uitextarea(g);

gb.HorizontalAlignment = 'center';

gb.Placeholder = 'text area place holder';

gb.Layout.Row = 1;

gb.Layout.Column = [2 6];

gb.Value = {'Program to calculate the minimum diamiter for a steel shaft with a shoulder fillet'};

% Create MaterialSelectionLabel

gc = uilabel(g);

gc.HorizontalAlignment = 'center';

gc.Layout.Row = 2;

gc.Layout.Column = [1 3];

gc.Text = 'Material Selection';

% Create TabGroup2

gd = uitabgroup(g);

gd.Layout.Row = [3 4];

gd.Layout.Column = [1 3];

% Create CustomTab

ge = uitab(gd);

ge.Title = 'Custom';

% Create TensileStrengthKsiEditFieldLabel

gf = uilabel(ge);

gf.HorizontalAlignment = 'right';

gf.Position = [24 134 91 30];

gf.Text = {'Tensile Strength'; '[Ksi]'};

% Create TensileStrengthKsiEditField

gg = uieditfield(ge, 'numeric');

gg.Limits = [50 250];

gg.Position = [130 142 100 22];

gg.Value = 50;

% Create YieldStrengthKsiEditFieldLabel

gh = uilabel(ge);

gh.HorizontalAlignment = 'right';

gh.Position = [35 76 80 30];

gh.Text = {'Yield Strength'; '[Ksi]'};

% Create YieldStrengthKsiEditField

gi = uieditfield(ge, 'numeric');

gi.Limits = [50 250];

gi.Position = [130 84 100 22];

gi.Value = 50;

% Create SurfaceFinishListBox_2Label

gj = uilabel(ge);

gj.HorizontalAlignment = 'right';

gj.Position = [288 166 81 22];

gj.Text = 'Surface Finish';

% Create SurfaceFinishListBox_2

gk = uilistbox(ge);

gk.Position = [282 76 150 90];

gk.Items={'Ground','Machined or Cold drawn','Hot-rolled','As-Forged'};

% Create DatabaseTab

gl = uitab(gd);

gl.Title = 'Database';

% Create MaterialSelectionListBoxLabel

gm = uilabel(gl);

gm.HorizontalAlignment = 'right';

gm.Position = [53 169 101 22];

gm.Text = 'Material Selection';

% Create MaterialSelectionListBox

gn = uilistbox(gl);

gn.Items = {'1006HR', '1006CD', '1010HR', '1010CD', '1015HR', '1015CD', '1018HR', '1018CD', '1020HR', '1020CD', '1030HR', '1030CD', '1035HR', '1035CD', '1040HR', '1040CD', '1045HR', '1045CD', '1050HR', '1050CD1', '060HR', '1080HR', '1095HR'};

gn.Position = [169 54 140 139];

gn.Value = '1006HR';

% Create DropDown

go = uidropdown(g);

go.Items = {'Custom', 'Database'};

go.Layout.Row = 2;

go.Layout.Column = 1;

go.Value = 'Custom';

% Create LoadslbinPanel

gp = uipanel(g);

gp.TitlePosition = 'centertop';

gp.Title = 'Loads [lb-in]';

gp.Layout.Row = [5 6];

gp.Layout.Column = [1 3];

% Create MaxMomentEditFieldLabel

gq = uilabel(gp);

gq.HorizontalAlignment = 'right';

gq.Position = [13 86 76 22];

gq.Text = 'Max Moment';

% Create MaxMomentEditField

gr = uieditfield(gp, 'numeric');

gr.Position = [104 86 100 22];

gr.Limits = [-60000 60000];

% Create MinMomentEditFieldLabel

gs = uilabel(gp);

gs.HorizontalAlignment = 'right';

gs.Position = [228 86 73 22];

gs.Text = 'Min Moment';

% Create MinMomentEditField

gt = uieditfield(gp, 'numeric');

gt.Position = [316 86 100 22];

gt.Limits = [-60000 60000];

% Create MaxTorqueEditFieldLabel

gu = uilabel(gp);

gu.HorizontalAlignment = 'right';

gu.Position = [21 38 68 22];

gu.Text = 'Max Torque';

% Create MaxTorqueEditField

gv = uieditfield(gp, 'numeric');

gv.Position = [104 38 100 22];

gv.Limits = [-60000 60000];

% Create MinTorqueEditFieldLabel

gw = uilabel(gp);

gw.HorizontalAlignment = 'right';

gw.Position = [236 38 65 22];

gw.Text = 'Min Torque';

% Create MinTorqueEditField

gx = uieditfield(gp, 'numeric');

gx.Position = [316 38 100 22];

gx.Limits = [-60000 60000];

% Create OptionsPanel

gy = uipanel(g);

gy.TitlePosition = 'centertop';

gy.Title = 'Options';

gy.Layout.Row = [7 8];

gy.Layout.Column = [1 3];

% Create ReliabilityListBoxLabel

gz = uilabel(gy);

gz.HorizontalAlignment = 'right';

gz.Position = [39 170 56 22];

gz.Text = 'Reliability';

% Create ReliabilityListBox

gaa = uilistbox(gy);

gaa.Items = {'50%', '90%', '95%', '99%', '99.9%', '99.99%'};

gaa.Position = [30 20 74 138];

gaa.Value = '50%';

% Create SafetyFactorEditFieldLabel

gbb = uilabel(gy);

gbb.HorizontalAlignment = 'right';

gbb.Position = [283 59 77 22];

gbb.Text = 'Safety Factor';

% Create SafetyFactorEditField

gcc = uieditfield(gy, 'numeric');

gcc.Limits = [1 Inf];

gcc.HorizontalAlignment = 'center';

gcc.Position = [272 28 100 22];

gcc.Value = 1;

% Create rdListBoxLabel

gdd = uilabel(gy);

gdd.HorizontalAlignment = 'center';

gdd.Position = [313 170 25 22];

gdd.Text = 'r/d';

% Create rdListBox

gee = uilistbox(gy);

gee.Items = {'.02(Sharp)', '.1(Well Rounded)'};

gee.Position = [245 103 161 55];

gee.Value = '.02(Sharp)';

% Create DdListBoxLabel

gff = uilabel(gy);

gff.HorizontalAlignment = 'right';

gff.Position = [163 170 25 22];

gff.Text = 'D/d';

% Create DdListBox

ggg = uilistbox(gy);

ggg.Items = {'1.10', '1.15', '1.20', '1.25', '1.30'};

ggg.Position = [137 20 77 138];

ggg.Value = '1.10';

% Create ResultsPanel

ghh = uipanel(g);

ghh.TitlePosition = 'centertop';

ghh.Title = 'Results';

ghh.Layout.Row = [3 6];

ghh.Layout.Column = [4 6];

% Create RunCalculationsButton

gii = uibutton(g, 'push');

gii.ButtonPushedFcn = matlab.apps.createCallbackFcn(comp, ...

@RunCalculationsButtonPushed, true);

gii.Layout.Row = [7 8];

gii.Layout.Column = [4 6];

gii.Text = 'Run Calculations';

RESULT={''};

gjj = uilabel(ghh, 'Position', [100 100 500 200],'Text',RESULT);

function RunCalculationsButtonPushed(~,~)

%custom vs dictionary input

k=go.ValueIndex;

%select sy and su based on custom vs database

if k==1

Su = gg.Value;

Sy = gi.Value;

%Material Finish Table

Finish_a=[1.34 2.7 14.4 39.9];

Finish_b=[-.085 -.265 -.718 -.955];

j=gk.ValueIndex;

ka=Finish_a(j)*Su^Finish_b(j);

else

%material dictionary

Material_names=['1006HR';'1006CD';'1010HR';'1010CD';'1015HR';...

'1015CD';'1018HR';'1018CD';'1020HR';'1020CD';'1030HR';...

'1030CD';'1035HR';'1035CD';'1040HR';'1040CD';'1045HR';...

'1045CD';'1050HR';'1050CD';'1060HR';'1080HR';'1095HR'];

Material_Su=[43; 48; 47; 53; 50; 56; 58; 64; 55; 68; 68; 76;...

72; 80; 76; 85; 82; 91; 90; 100; 98; 112; 120];

Material_Sy=[24; 41; 26; 44; 27.5; 47; 32; 54; 30; 57; 37.5;...

64; 39.5; 67; 42; 71; 45; 77; 49.5; 84; 54; 61.5; 66];

Material_table=table(Material_names,Material_Su,Material_Sy);

indx1=gn.ValueIndex;

Su=Material_Su(indx1);

Sy=Material_Sy(indx1);

ka=1;

end

%Size factor Kb, initial=.9

kb=1;

%Kc=1 Kd=1

%reliability factor Ke

Realiability_choice=gaa.ValueIndex;

if Realiability_choice==1%reliability == 50

ke=1;

elseif Realiability_choice==2%reliability == 90

ke=.897;

elseif Realiability_choice==3%reliability == 95

ke=.868;

elseif Realiability_choice==4%reliability == 99

ke=.814;

elseif Realiability_choice==5%reliability == 99.9

ke=.753;

elseif Realiability_choice==6%reliability == 99.99

ke=.702;

end

%overall endurance limit

if Su<=200

Se_prime=.5*Su*1000;%psi

else

Se_prime=100*1000;%psi

end

%endurance limit Se at filet initial

Se = ka*kb*ke*Se_prime;

%first guess Kf and Kfs

shoulder_type=gee.ValueIndex;

if shoulder_type == 1

Kf=2.7; Kfs=2.2; r_d=.02;

elseif shoulder_type == 2

Kf=1.7; Kfs=1.5; r_d=.1;

end

%factor of safety

n = gcc.Value;

%impory T and M

T_max = gv.Value;

T_min = gx.Value;

M_max = gr.Value;

M_min = gt.Value;

%check T and M delta is positive

if M_min > M_max

uialert(comp,"Ensure that Minimum moment is less than or equal to Maximum moment","Moment Error");

end

if T_min > T_max

uialert(comp,"Ensure that Minimum torque is less than or equal to Maximum torque","Torque Error");

end

%mean and alternating T and M

Ta=(T_max-T_min)/2;%lb-in

Tm=(T_max+T_min)/2;%lb-in

Ma=(M_max-M_min)/2;%lb-in

Mm=(M_max+M_min)/2;%lb-in

%getting first estimation of diamiter using goodman

di(1)=(16*n/pi* (sqrt(4*(Kf*Ma)^2+3*(Kfs*Ta)^2)/Se +...

sqrt(4*(Kf*Mm)^2+3*(Kfs*Tm)^2)/Su/1000))^(1/3);

%now can get to iteration stage

D_d=str2double(ggg.Value);

%find Kt, using interpolation from fesired D/d

if D_d>1.2

Kt_b=.93836 * r_d ^ -.25759;%line at 1.5

Kt_a=.97098 * r_d ^ -.21796;%line at 1.2

Kt=Kt_a + (Kt_b-Kt_a)/(1.5-1.2)*(D_d-1.2);

elseif D_d<=1.2

Kt_b=.97098 * r_d ^ -.21796;%line at 1.2

Kt_a=.95120 * r_d ^ -.23757;%line at 1.1

Kt=Kt_a + (Kt_b-Kt_a)/(1.2-1.1)*(D_d-1.1);

end

%find Kts, using interpolation from desired D/d

if D_d>1.2

Kts_b=.84897 * r_d ^ -.23161;%line at 1.33

Kts_a=.83425 * r_d ^ -.21649;%line at 1.2

Kts=Kts_a + (Kts_b-Kts_a)/(1.33-1.2)*(D_d-1.2);

elseif D_d<=1.2

Kts_b=.83425 * r_d ^ -.21649;%line at 1.2

Kts_a=.90337 * r_d ^ -.12692;%line at 1.09

Kts=Kts_a + (Kts_b-Kts_a)/(1.2-1.09)*(D_d-1.09);

end

%loop begins only recalculating factor that depend on the diamiter of the

%shaft

k=2;

dd=1;

%only stops after the % error between the last 2 diamiter iterations are

%less than 0.1%

while dd>=.001

%find q

a_sqrt=.246-3.08*(10^-3)*Su+1.51*(10^-5)*Su^2-2.67*(10^-8)*Su^3;

r=r_d*di(k-1);

q=1/(1+a_sqrt/sqrt(r));

%find qs

as_sqrt=.190-2.51*(10^-3)*Su+1.35*(10^-5)*Su^2-2.67*(10^-8)*Su^3;

qs=1/(1+as_sqrt/sqrt(r));

%finding Kf and Kfs

Kf=1+q*(Kt-1);

Kfs=1+qs*(Kts-1);

%finding size factor kb accurately

if di(k-1)<.3

kb=(.3/.3)^-.107;

elseif di(k-1)>=.3 && di(k-1)<=2 %in

kb=(di(k-1)/.3)^-.107;

elseif di(k-1)>2 && di(k-1)<=10

kb=.92*di(k-1)^-.157;

elseif di(k-1)>10

kb=.92*di(k-1)^-.157;

end

%new endurance limit at critical point

Se = ka*kb*ke*Se_prime;

di(k)=(16*n/pi* (sqrt(4*(Kf*Ma)^2+3*(Kfs*Ta)^2)/Se +...

sqrt(4*(Kf*Mm)^2+3*(Kfs*Tm)^2)/Su/1000))^(1/3);

dd=abs((di(k)-di(k-1))/di(k-1));

k=k+1;

%check von mises for yielding

Sigma_von_a=sqrt((32*Kf*Ma/pi/di(k-1)^3)^2+3*(16*Kfs*Ta/pi/di(k-1)^3));

Sigma_von_m=sqrt((32*Kf*Mm/pi/di(k-1)^3)^2+3*(16*Kfs*Tm/pi/di(k-1)^3));

Sigma_von_max=Sigma_von_a+Sigma_von_m;

ny=Sy/Sigma_von_max*1000;

end

if ny<1

%if yields give recomendations and ask for new inputs

uialert(comp,"input conditions will lead to a shaft that yields. Please choose do one of the following" + ...

" choose a different material with a higher yielding stress" + ...

"decrease the loads that the shaft experience","Yield Error");

gjj.Text ={''};

else

%if doues not yield, output athe converged diamiters

d=di(k-1);

D=D_d*d;

gjj.Text = {'minimum diameter for smaller side of rod [d]';'';

[' d = ',num2str(d),' in']; '';'';'';...

'minimum diameter for larger side of rod [D]';''; ...

[' D = ',num2str(D),' in']};

end

end

end